Where's the money?

Let's not mince words.

Respect profitability as a priority.

Understand implications of actions. Understand existing systems and practices. Understand the humans and the roles they fill now and how those roles will be affected by change. Understand what is currently available and what needs to change. Be informed. Be smart. Keep it simple. Think broadly and over time through the sequences of transactions and triggers from one end to the other. These are supply and demand systems, supply chains.

Make this a priority but don't rush. One wrong turn of a ship in the Suez Canal can have huge implications worldwide.

This article describes just one piece of The New Model of Distribution of Recaptured Building Materials, speaking to the sources of income and savings. There is more to The New Model, but for another time.

One sentence does tell where we are headed with this, though: We must make reclaimed building materials available to the Architecture, Engineering, and Construction community in the same ways that new materials are made available to them.

Environmental and social benefits have not been enough to inspire adequate change. Witness where we are in this now. Profit is really the driver of the whole thing: respecting and enhancing profit. When we do that, we are still doing the right thing for our future, just going about it a different way and with less friction.

We have tried the current ways up to now. Why not admit that the current ways are not working? Let's instead work with rather than against the driving factor in our economy: profit.

To do this with recaptured building materials, we must tap into the biggest potential untapped market, the AEC community: Architecture, Engineering, and Construction. Let's add to this the building owners: the developers, the real estate portfolio groups, the governments, and individual owners, since they are the ones who pay the architects, engineers, and contractors.

So where is the money? Keep in mind that we are not Financial Planners, CPAs, nor financial or legal experts. These points are for general information and a useful starting point of further exploration.

Following here is an incomplete list, but it is a good start. The TL;DR (Too Long; Didn’t Read) list of KEY ingredients is here first:

1) Expanded demand

2) Tax benefits

3) Scale

4) New business models

5) Competition

6) Technology and tools

7) Cost savings

8) Sales

9) Real estate

10) Job creation

11) Incentives

12) Grants

13) Stable Supply Chains

14) Standardization and sharing

15) Policy

The expanded list starts here:

1) Expanded demand – Make these products available to the largest available audience by virtue of new trusted suppliers and supplies to AEC (Architecture, Engineering, and Construction) and building owners and developers. Work regionally. Establish seller to buyer relationships by one product type at a time, like lumber. Repeat and expand to additional materials, like structural steel.

2) Tax benefits - Tax deductions made available by donating materials removed from a building project to a qualified non-profit organization and then deducting the amount from taxable income. Who can get these benefits?

a) Individuals.

b) Small businesses.

c) Corporations.

3) Scale – To scale means to increase size in multiples, in this case with efficiency of processing, storage facility numbers and capacities, and increased inventory availability. At the "scale" (as in the large spaces) of a Costco-sized warehouse, you can do things you cannot do in a small, urban retail selling store with customers and salespeople and the unpredictability those entail. Here we advocate for larger, all wholesale processing centers in low cost areas central to a region of population centers, on a highway and ideally a rail line.

a) Costs are minimized by lower real estate costs, employee specialization, and by overall efficiency.

b) Job roles at large scale:

i) Those who sort and identify materials and apply labels for Unique identifiers: bar codes QR codes, RFID codes, SKUs, etc. attached to each item.

ii) Ecommerce - inputters of information and images about each material efficiently.

iii) Inventory managers.

iv) Warehousing managers.

v) Forklift operators.

vi) Shipping – Those who prepare for shipment plus having machinery and supplies to package for shipment.

c) Machinery at large scale:

i) AI-enabled material identifiers.

ii) Measuring equipment that inputs measurements into databases for you.

iii) Finger-joining machines.

iv) Robotic materials sorters.

v) Banders and wrappers.

vi) Forklifts.

d) Storage capacity at large scale:

i) Larger projects need bigger quantities of materials.

ii) They need variety from which to choose.

iii) They need to be well-organized and easily identified.

iv) They need to be easy to move and to prepare for shipment.

v) They need to be made available in the current systems by which the AEC community sources and purchases materials, just like new.

e) Other benefits of larger scale facilities:

i) Few interruptions of workflow.

ii) Efficient storage, shipping, and distribution

iii) Choice / variety / quantity / dependability / availability of many recaptured materials.

4) New business models - and new businesses.

a) Marketplaces, like ReCapturit (our former website, the marketplace until August, 2025).

b) Materials exchanges.

c) Processing facilities.

d) Haulers.

e) Deconstruction companies.

f) New Retailing models with ample online capabilities and inventory understanding.

5) Competition – As The New Model begins, the “Flywheel Effect” begins, gathering speed and momentum until it becomes unstoppable.

6) Technology and tools - Integration of new and needed technology and tools for:

a) Inventory management – efficient tracking of all the materials and immediate knowledge of stock levels and location, plus data and reports to better understand demands and more.

b) Warehouse management - efficient optimization of spatial requirements for maximizing capacity and minimizing moving of materials.

c) Processing - identifying, sorting, measuring, weighing, photographing, inputting into inventory, preparing for sale and distribution.

d) Testing for structural integrity and adherence to specs.

e) Grading of lumber.

f) Testing of structural steel.

g) Immediate transformation of materials such as using pieces of lumber for finger joining to make standardized lengths, etc.

h) Metal removal from lumber - nails, screws, staples, bolts.

i) Analyzing existing buildings for materials identification, determination of quantities, categorization, compilation, and valuation of the current worth of materials in a building. This is new.

j) Tools for identifying and categorizing and storing information in systems for inventory, lifecycle tracking, sales, carbon footprint and embodied carbon , ecommerce, architectural drafting and costing, and BIM.

7) Cost savings - By virtue of scale and wholesale processing without the retail component, diminished fees paid to landfills and transfer stations, extended lives of landfills meaning expanded value of those capital-intensive projects, and more. Materials can be free or better than free – someone pays you to take them away.

8) Sales – Selling reclaimed materials through multiple channels.

a) Brokered deals - finding quantities of materials available and executing a sale between the owner and a buyer of those materials.

b) On-site sales prior to deconstruction - photographing and identifying and valuing a building component or lot of materials and establishing a selling agreement prior to the removal of the items.

c) Salvage stores.

d) Used lumber wholesalers.

e) Furniture makers, crafts, artisans, and various manufacturers.

f) Ecommerce marketplaces, exchanges, directories, and websites, potentially inter-connected across platforms to facilitate greater audience reach and pricing.

9) Real estate – Properties for storage and processing with agreements for shared responsibility of ownership and dispersed costs between government and business. Leases, sales, accumulation of appreciating assets.

10) Job creation - Plus career advancement opportunities in deconstruction, processing, and warehousing.

a) Reuse of materials through deconstruction requires nearly a dozen times the human work of demolition and direct disposal. That means jobs.

b) With some types of building deconstruction, there are few skills required to enter the trade, but in commercial deconstruction of multi-story buildings, this requires a high level of skills.

c) Within the processing facilities of the future, there will be manual labor as well as jobs with computer skills needed, and even people to run robotics and other machinery. Each facility can be a training ground and a career path toward higher skills and greater transferability of skills to other jobs and increasing pay.

11) Incentives – Clever financial and temporal benefits for using reclaimed materials and for choosing deconstruction over demolition, most often offered by local government.

12) Grants – US EPA and other agencies offer grants that can fuel this growth.

13) Stable Supply Chains – These products are on-shore. They are available. They do not incur tariffs and sluggish international relations. They do not cross international borders unless to ship outbound.

14) Standardization and sharing – Communicate widely best practices and successful systems, including policy, inventory, embodied carbon and life cycle tracking.

15) Policy – Careful, thoughtful policy can stimulate, incentivize, organize, and standardize systems without being heavy-handed or costly, if… IF there is ample understanding of current conditions, regional economies, current and needed workforce, social ramifications, and planning with all stakeholders involved. These are followed by a monitored implementation and execution of the plan, adjusting as needed over time.

16) Code modification – Building codes are important. Modifying them can be extremely slow. Using examples of code changes already implemented elsewhere is helpful. There are some, such as the allowance for used lumber to be used in structural situations without a grade stamp, simply by downgrading all used lumber to the lowest value species grade. Progress is happening.

17) Compliance - More specifically, ease of compliance, is not just desirable but crucial. Without high compliance, why build the system? Incorporating complexity and hindrances hinder. This leads to non-compliance. Build those out. Respect those who are affected. Understand how they work now and how they will need to work under new policy. Simple and mindful or profit beats complex and unaware.

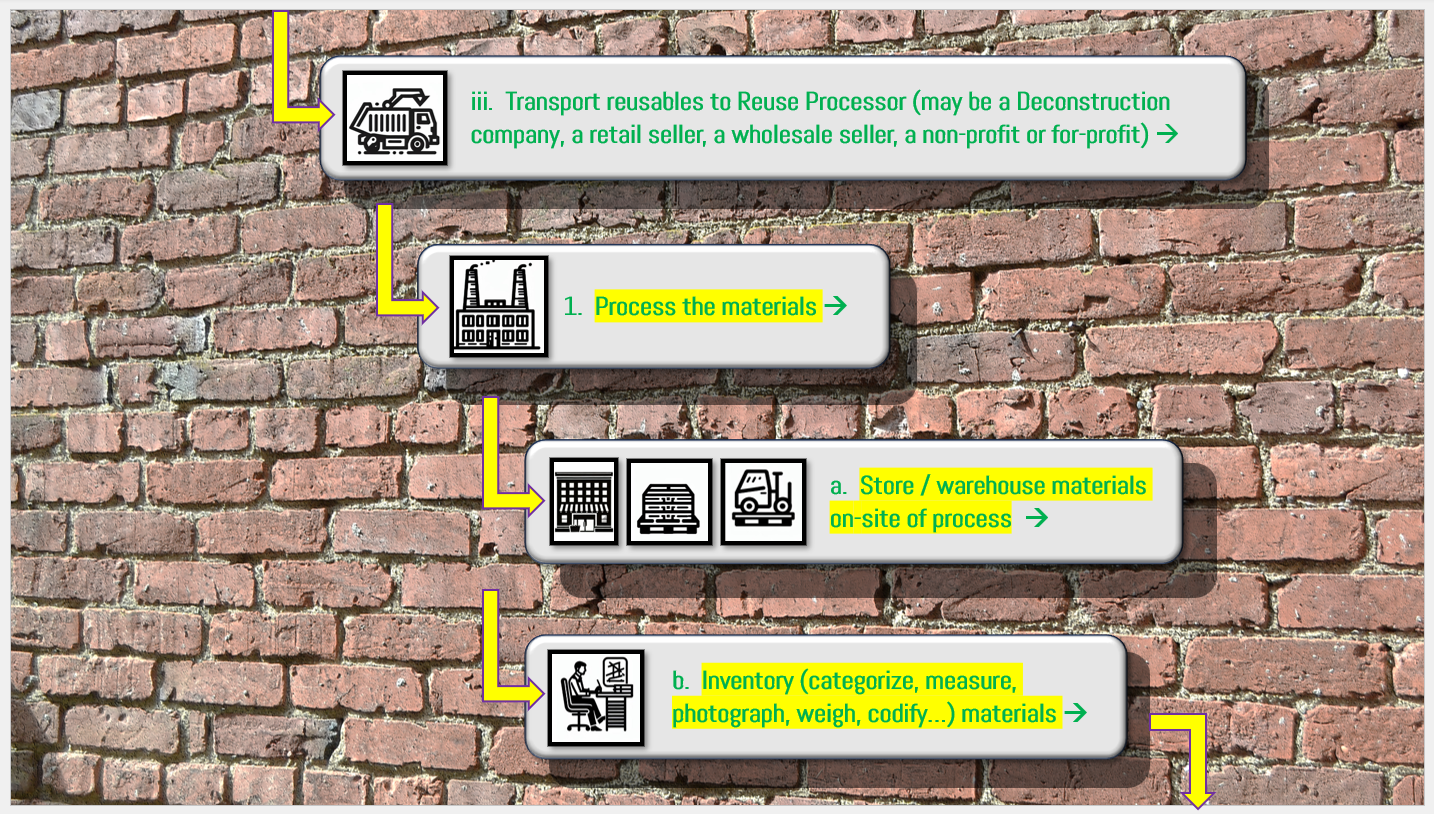

18) Sourcing - Gather materials from all five main sources for processing, distribution, and sale for incorporation into new products and new construction. There are vast quantities of materials that could be made available for lower-cost housing and other worthwhile pursuits, rather than to let these valuable materials and products sit and collect dust and cost their owners. Here are the five:

a) Demolition

b) Deconstruction

i) Pre-demolition "skimming" of valuable materials and components, plumbing, lighting, etc.

ii) Mid-demolition removal of large high-value materials (trusses, timbers, etc.)

iii) Full Deconstruction (except for concrete foundations, typically)

c) Construction jobsite materials from:

i) New construction

ii) Renovation, retrofit, remodeling

(1) "Old" materials extracted prior to new work.

(2) "New" materials from overages, cutoffs, temporary use, etc.

iii) Tenant Improvements (TI’s)

d) Surplus

i) Discontinued products

ii) Overages – over-stocked, over-produced

iii) Returns

iv) Seconds and damaged

e) "Urban Mining" - this term covers more than building materials and refers to proactively extracting usable materials, machinery, electronics, and more. For building materials, it can mean assessing the value of a currently standing but abandoned building and disassembling it for the value of the materials. See "Analyzing existing buildings..." below, under Technologies.

19) Discriminating Buyers and users: exercising choice for sustainability, style, fashion, history, etc.

20) Simplicity - the current ecosystem of distribution of recaptured building materials is not simple. It is a distributed set of multitudinous individual efforts and accumulated practices, mostly connected only by purpose and lack of modern technology, not by methods nor technological advancements nor centralized distribution nor processing efficiencies. This is costly to us all. The New Model of Distribution of Recaptured Building Materials creates a much more efficient system that processes far greater quantities, eliminating the practice of wasting valuable resources. It is simple.

21) Other Efficiencies

a) Data accumulation and tracking of materials geographically and over their life spans.

b) Analysis of movements of materials to create greater efficiency and lower carbon footprint.

To sum it up, there are many avenues to revenues and savings. As savvy investors know about business ecosystems, as The New Model of Distribution of Recaptured Building Materials grows and finds its way into the AEC community and receptive minds of developers and building investors, the “Flywheel Effect” will accelerate. This will become the norm. Architects will seek reclaimed products as easily as new ones. Builders will purchase them from trusted online sources. Developers and owners will receive myriad benefits, including financial and sustainability benefits.

Remember, Waste Is Not Waste Until It Is Wasted.

We can stop the wasteful practices and improve profitability all at once.

What would YOU add to the list?

Larry

PLEASE SHARE and re-post this. This is important. Thank you.

#reuse #recycling #buildingmaterials #sustainability #waste #zerowaste #construction #architecture #design #reclaimedbuildingmaterials #recapturit #urbanplanning #reclaimed